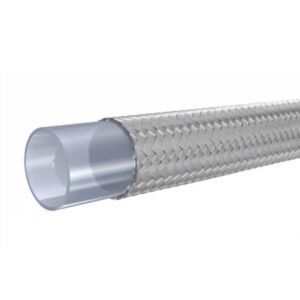

Inner Tube: Synthetic rubber with oil resistance, black color

Reinforcement Layer: Single layer of high-strength braided steel wire

Outer Cover: Synthetic rubber with oil, weather, abrasion, and corrosion resistance, black color

Surface: wrapped or smooth surface

Temperature Range: -40℃ – +100℃

Product Description

SAE 100 R1 reinforced hydraulic hose is widely employed for medium-pressure hydraulic systems. It can work under higher pressure compared to other rubber hoses owing to its high tensile braided steel wire reinforcement.

The hose comprises the inner tube, reinforcement, and outer cover. The tube is made from synthetic rubber with excellent oil resistance features, which allows the hose to deliver oils or fluids more effectively. The reinforcement layer comprises one single layer with high-tensile braided steel wire. It makes the hose work well in high-pressure applications. The outer cover is made from rigid synthetic rubber, which keeps the hose resistant to weather, aging, abrasion, corrosion, etc.

Features And Benefits

Oil, weather, corrosion, and abrasion resistant

Broad temperature ranges from -40°C to +100°C

A highly flexible and solid structure delivers a longer service life

Hydraulic Rubber Hose Application

It is suitable for various low-medium pressure hydraulic applications. Such as hydraulic engines, mine hydraulic support, forklift truck, oilfield exploitation equipment, and mine, road, and construction machinery.

Technical Data Sheet

|

DN |

Hose ID |

Wire O.D |

Hose O.D |

Max.Working Pressure |

Min.Burst Pressure |

Min. Bend Radius |

|||

|

inch |

mm |

mm |

mm |

Mpa |

Psi |

Mpa |

Psi |

mm |

|

|

5 |

3/16″ |

4.8 |

9.5 |

11.8 |

25.0 |

3625 |

100.0 |

14500 |

90 |

|

6 |

1/4″ |

6.4 |

11.1 |

13.4 |

22.5 |

3270 |

90.0 |

13050 |

100 |

|

8 |

5/16″ |

7.9 |

12.7 |

15.0 |

21.5 |

3120 |

86.0 |

12470 |

115 |

|

10 |

3/8″ |

9.5 |

15.1 |

17.4 |

18.0 |

2610 |

72.0 |

10440 |

125 |

|

13 |

1/2″ |

12.7 |

18.3 |

20.6 |

16.0 |

2320 |

64.0 |

9280 |

180 |

|

16 |

5/8″ |

15.9 |

21.4 |

23.7 |

13.0 |

1890 |

52.0 |

7540 |

205 |

|

19 |

3/4″ |

19.0 |

25.4 |

27.7 |

10.5 |

1530 |

42.0 |

6090 |

240 |

|

25 |

1″ |

25.4 |

33.3 |

35.6 |

8.8 |

1280 |

35.0 |

5070 |

300 |

|

32 |

1 1/4″ |

31.8 |

40.5 |

43.5 |

6.3 |

920 |

25.0 |

3600 |

420 |

|

38 |

1 1/2″ |

38.1 |

46.8 |

50.6 |

5.0 |

725 |

20.0 |

2900 |

500 |

|

51 |

2″ |

50.8 |

60.2 |

64.0 |

4.0 |

580 |

16.0 |

2320 |

630 |