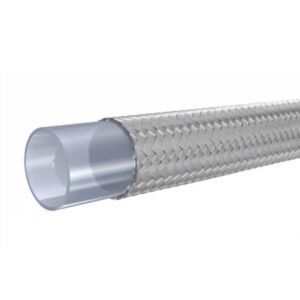

Inner Tube: Black color, synthetic rubber, oil resistant

Reinforcement Layer: One single layer of braided steel wire

Outer Cover: Black color, one fiber braided

Temperature Range: -40℃ – +100℃

Product Description

SAE 100 R5 steel wire reinforced and fiber braided hydraulic hose is an ideal choice for applications where medium pressure and impulse fatigue resistance are required, including petroleum-based hydraulic fluids, lubricating oils, water, and air piping, air brake systems, power steering, fuel filter, turbo oil lines, and tilt cab cylinders. It comprises an inner tube, reinforcement, and outer cover. The tube is composed of oil-resistant and heat-insulating synthetic rubber, providing an excellent channel to transfer oils or fluids between different components. The reinforcement is made of one single layer of braided steel wire, providing the hose with a solid structure. The outer cover comprises braided fiber, providing the hose weather, aging, and corrosion resistance.

Features And Benefits

Oil, weather, aging resistance, and heat insulation properties

It has an extensive temperature range from -40°C to +100°C

Able to work in medium-pressure and high-temperature applications

Meets or exceeds requirements of SAE 100R5

Hydraulic Rubber Hose Application

Recommended for medium-pressure hydraulic oil lines or systems, such as hydraulic engines, oilfield exploitation equipment, forklift, mine, road, construction machinery, etc.

Technical Data Sheet

|

DN |

Hose I.D |

Hose O.D. |

Max. Working Pressure |

Min. Burst Pressure |

Min. Bend Radius |

|||

|

inch |

mm |

mm |

Mpa |

Psi |

Mpa |

Psi |

mm |

|

|

5 |

3/16″ |

4.8 |

13.2 |

21 |

3050 |

84 |

12180 |

75 |

|

6 |

1/4″ |

6.4 |

14.8 |

21 |

3050 |

84 |

12180 |

85 |

|

8 |

5/16″ |

7.9 |

17.1 |

15.7 |

2280 |

62.8 |

9100 |

100 |

|

10 |

13/32″ |

10.3 |

19.5 |

14 |

2030 |

56 |

8120 |

115 |

|

13 |

1/2″ |

12.7 |

23.4 |

12.2 |

1770 |

48.8 |

7080 |

140 |

|

16 |

5/8″ |

15.9 |

27.4 |

10.5 |

1520 |

42 |

6090 |

165 |

|

22 |

7/8″ |

22.2 |

31.4 |

5.6 |

812 |

22.4 |

3250 |

185 |

|

28 |

1 1/8″ |

28.6 |

38.1 |

4.3 |

630 |

17.2 |

2500 |

230 |

|

35 |

1 3/8″ |

34.9 |

44.4 |

3.5 |

510 |

14 |

2030 |

265 |

|

46 |

1 13/16″ |

46.0 |

56.4 |

2.4 |

350 |

9.6 |

1400 |

335 |

|

60 |

2 3/8″ |

60.3 |

73 |

2.4 |

350 |

9.6 |

1400 |

610 |

|

76 |

3″ |

76.2 |

90.5 |

1.4 |

200 |

5.6 |

810 |

840 |