Tube: synthetic rubber with resistance to oil and hydraulic fluids

Reinforcement: one single or double layers of high-tensile steel wire

Cover: weather and abrasion-resistant synthetic rubber

Temperature: -40℃ – +100℃

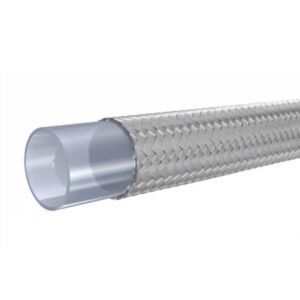

Product Description

Thanks to a tighter bending radius and exterior diameter, SAE 100 R17 steel wire-reinforced hydraulic hose is ideal for specific devices requiring narrow installation space. It is composed of the inner tube, reinforcement, and outer cover. The tube is formed with synthetic rubber, which is oil resistant, making it perfect for use in conveying hydraulic fluids. The reinforcement is reinforced with one single or double layer of high tensile braided steel wire. It will provide excellent support for the hose to operate at high working pressure. The cover is made from ultra-high quality oil and weather-resistant synthetic rubber, which protects the hose against weather, aging, abrasion, corrosion, ozone, etc.

Features And Benefits

High tensile steel wire reinforced makes the hose durable to use.

Designed for high-pressure hydraulic oil lines.

Exceeding the performance requirements of SAE 100 R17 and EN 857 1SC.

Smaller size and tighter bend radius compared to SAE 100 R1 and SAE 100 R2 hoses.

Hydraulic Rubber Hose Applications

It is mainly used for high-pressure hydraulic systems with oil and water-based fluids or industrial and agricultural use.

Technical Data Sheet

|

DN |

Hose I.D |

Hose O.D |

Max. Working Pressure |

Min. Burst Pressure |

Min. Bend Radius |

|||

|

inch |

mm |

mm |

Mpa |

Psi |

Mpa |

Psi |

mm |

|

|

5 |

3/16″ |

4.8 |

10.6 |

21 |

3050 |

84 |

12180 |

45 |

|

6 |

1/4″ |

6.4 |

11.9 |

21 |

3050 |

84 |

12180 |

50 |

|

8 |

5/16″ |

7.9 |

13.6 |

21 |

3050 |

84 |

12180 |

55 |

|

10 |

3/8″ |

9.5 |

15.3 |

21 |

3050 |

84 |

12180 |

65 |

|

13 |

1/2″ |

12.7 |

18.9 |

21 |

3050 |

84 |

12180 |

90 |

|

16 |

5/8″ |

15.9 |

24.4 |

21 |

3050 |

84 |

12180 |

100 |

|

19 |

3/4″ |

19.1 |

28.3 |

21 |

3050 |

84 |

12180 |

120 |

|

25 |

1″ |

25.4 |

35.5 |

21 |

3050 |

84 |

12180 |

150 |